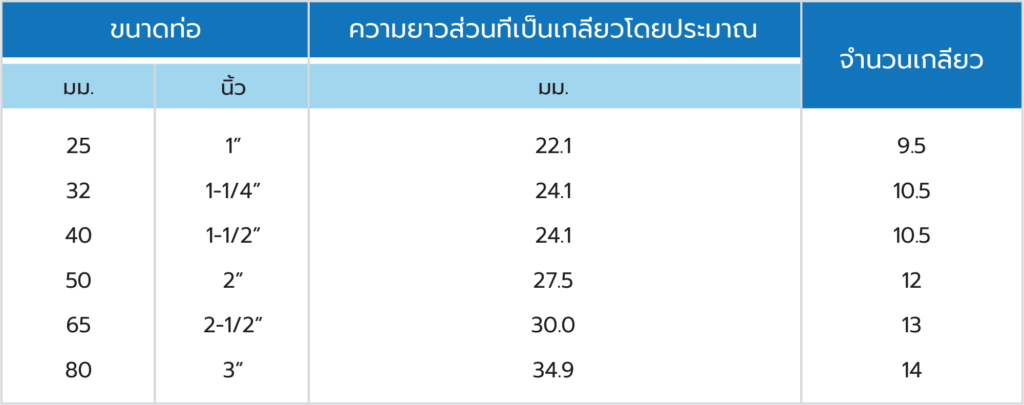

การติดตั้งท่อประปาของท่อเหล็กชุบสังกะสี มักจะนิยมติดตั้งแบบขันเกลียว โดยมาตรฐานเกลียวของท่อและข้อต่อที่ใช้ในการต่อท่อประปา จะอ้างอิงตามมาตรฐาน BS21 และ BSPT เพราะเป็นมาตรฐานที่นิยมใช้สำหรับท่อประปาในเมืองไทย โดยทำเกลียวแบบ Taper ตามมาตรฐานจะมีการกำหนดจำนวนเกลียวต่อระยะ 25.44 mm สำหรับท่อขนาดต่างๆ และความยาวเกลียวโดยประมาณ การติดตั้งท่อประปาแบบเกลียวจะนิยมใช้สำหรับท่อประปาขนาดเล็ก เพราะสามารถนำเครื่องการต๊าปเกลียวไปตัดและต๊าปเกลียวได้ที่หน้างาน ติดตั้งง่ายเหมือนท่อเหล็กทั่วไป โดยการติดตั้งท่อประปาของท่อและข้อต่อไซเลอร์ ประกอบด้วยรายละเอียดดังนี้

การติดตั้งท่อประปาเหล็กบุพีอีไซเลอร์ สามารถทำได้ง่ายเหมือนการติดตั้งท่อประปา

เหล็กทั่วไป ต้องให้ความสำคัญตั้งแต่การตัดท่อ การตัดท่อต้องให้ได้ฉาก 90° ทุกครั้ง

Steel Pipe Cutting Machine

เครื่องตัดท่อเหล็ก ไร้ประกายไฟ

ยี่ห้อ TUWEI รุ่น TWQ-3A รุ่น TWQ-IIIA

เครื่องตัดท่อเหล็ก ไร้ประกายไฟ TUWEI รุ่น TWQ-3A ใช้ตัดท่อเหล็กด้วยระบบไฮดรอลิคได้รวดเร็ว

โดยไร้ประกายไฟตัวเครื่องมีด้ามจับแบบเหล็กใช้งานง่าย สะดวกในการเคลื่อนย้ายด้วยล้อเลื่อน 2 ล้อ

รายละเอียดสินค้า

ติดต่อสอบถามรายละเอียดเพิ่มเติม โทร. 02 634 9981 -4

www.grooving-machine.com

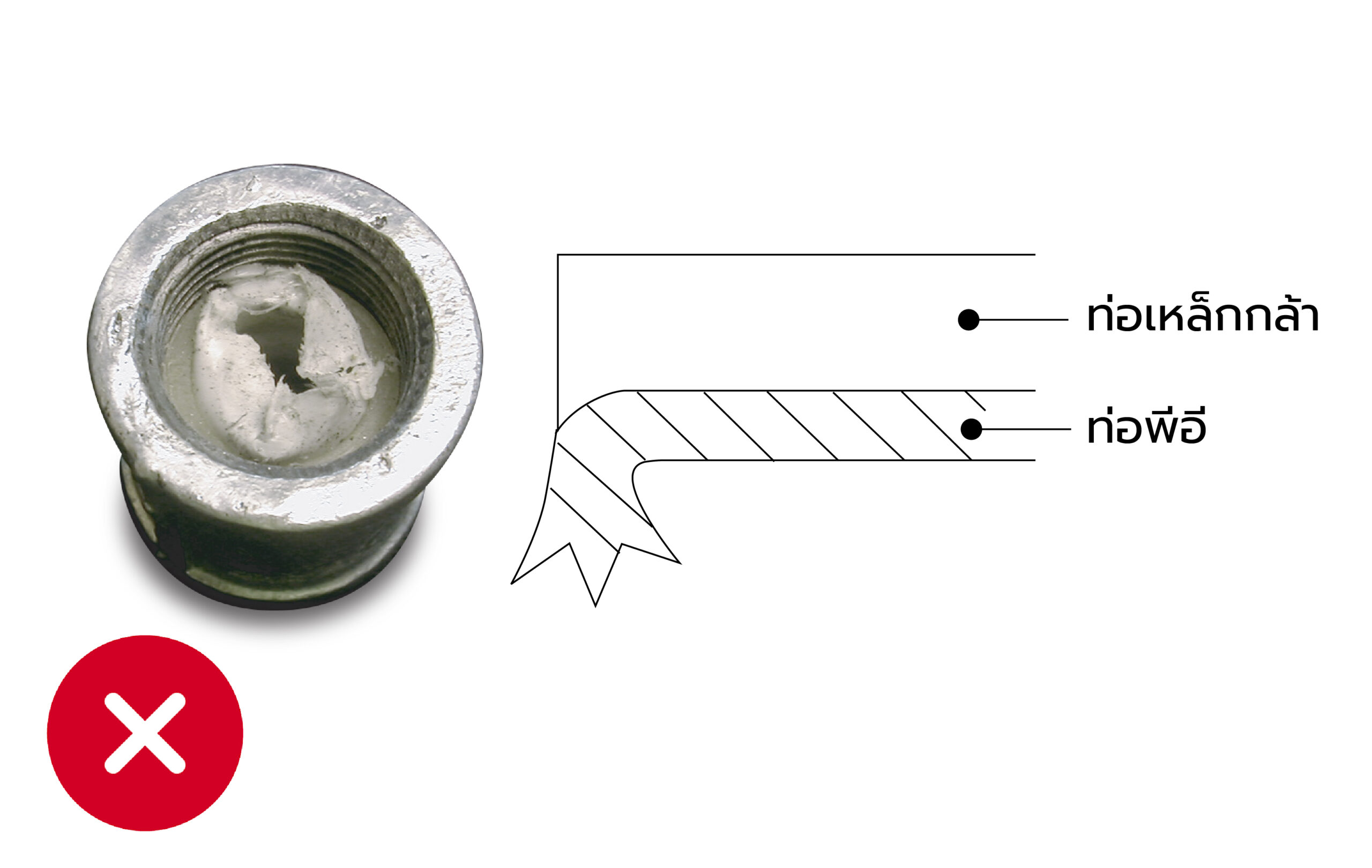

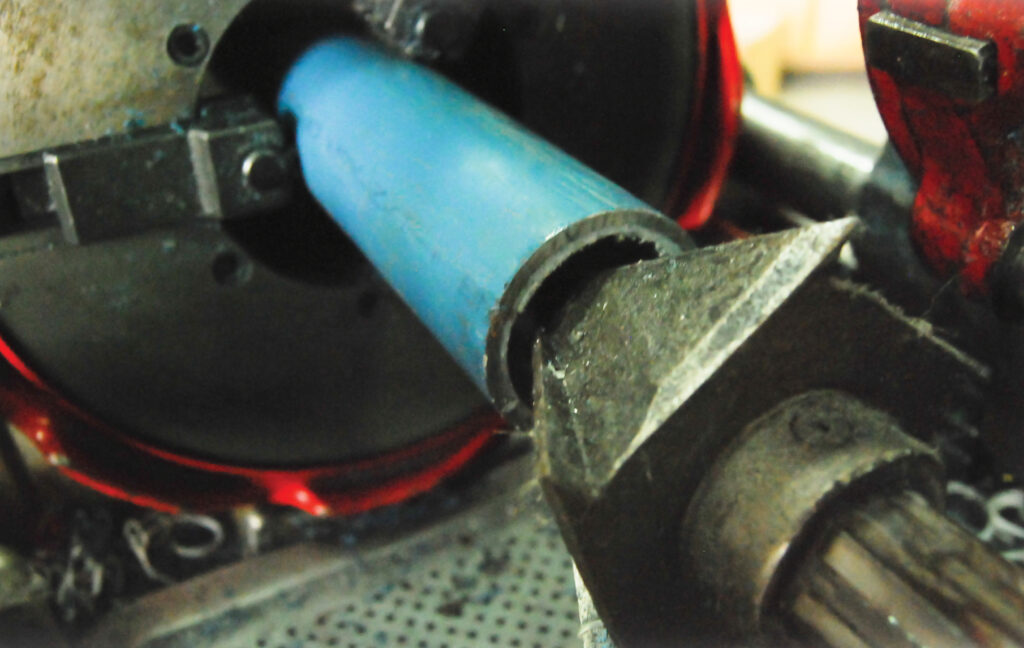

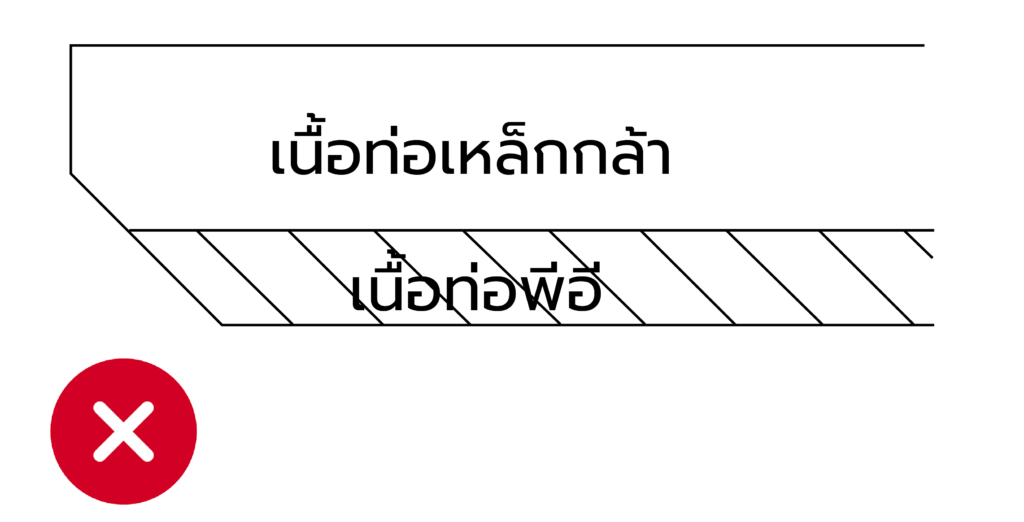

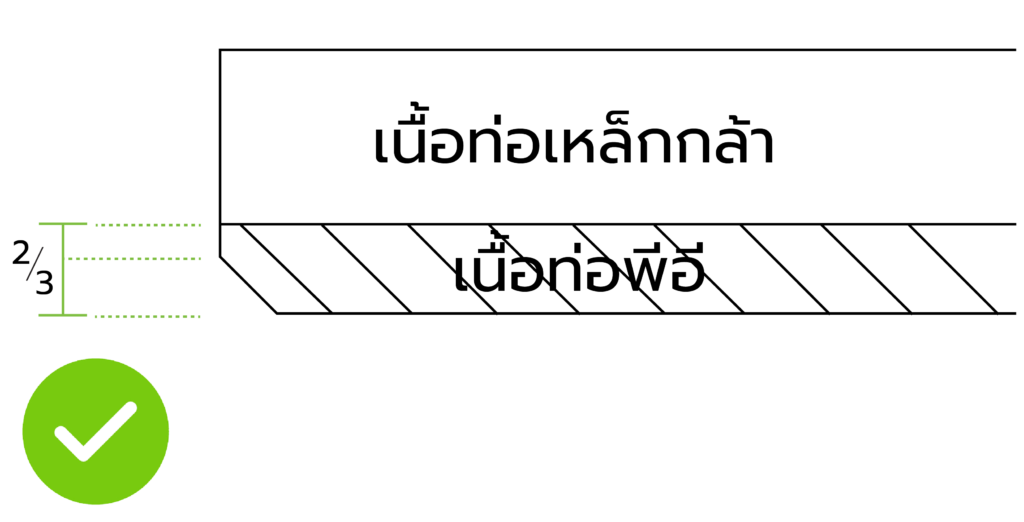

ควรใช้เครื่องมือคว้านท่อ (Scraper) ที่ติดตั้งในเครื่องต๊าปเพื่อกำจัดในส่วนที่ไม่เรียบ ซึ่งหากไม่ทำการแต่งปลายท่ออาจมีผลทำให้พลาสติกด้านในข้อต่อเสียหายจนไปขวางการไหลของน้ำให้ลดน้อยลงได้เช่นกัน

หากขูดหรือแต่งปลายท่อด้วยเครื่องมือคว้านท่อที่ติดตั้งในเครื่องต๊าป ต้องไม่ให้ปลายท่อถูกขูดไปเกิน 2 ใน 3 ของความหนาชั้นพีอี และถ้าไม่แต่งปลายท่อก่อนขันเกลียว อาจทำให้ภายในของข้อต่อเกิดความเสียหายได้

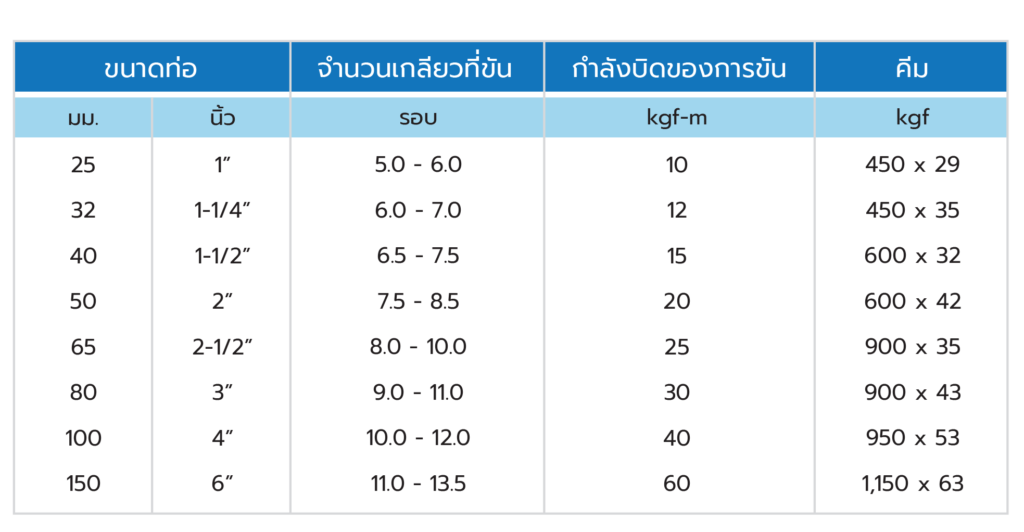

การทำเกลียวท่อและข้อต่อไซเลอร์ ควรทำเกลียวเพื่อให้ได้ความยาวของเกลียวตามมาตรฐาน BS21 และ BS PT ตามตารางด้านล่างเพื่อป้องกันการรั่วและเกิดสนิมของท่อและข้อต่อ ได้อย่างมีประสิทธิภาพ

ในระหว่างขั้นตอนการทำเกลียว ควรเร่งน้ำมันต๊าปหรือสารหล่อเย็นในระดับสูงสุด เพื่อป้องกันความร้อนสะสมที่เกิดขึ้นระหว่างทำเกลียว ซึ่งอาจทำให้ชั้นพีอีเสียหายได้และควรให้น้ำมันต๊าป หรือสารหล่อเย็นที่ผู้ผลิตเครื่องต๊าปแนะนำ

เครื่องต๊าป มีปัญหาเกี่ยวกับการใช้เครื่องต๊าป กรุณาติดต่อผู้ผลิต หรือจัดจำหน่าย บริษัท ที.ซี.อิมปอร์ต แอนด์ เอ็กปอร์ต จำกัด

ติดต่อฝ่ายขาย และ ศูนย์บริการ Tel. 02-042-9958-59 , Fax. 02-130-2038 Mobile. 081-820-7037 (ตั้ม) , 089-923-1238 (วุฒิ)

(เปิดบริการทุกวัน จันทร์-เสาร์ ตั้งแต่เวลา 8.30 น. – 17.30 น.)

ปกติท่อไซเลอร์นั้น ด้านนอกของท่อเหล็กจะชุบซิงค์(สังกะสี) ป้องกันสนิม แต่ในส่วนของการต๊าปเกลียวจำเป็นต้องขูดลอกผิวสังกะสีออก เหลือแต่เพียงเนื้อเหล็กอย่างเดียว จึงเกิดปัญหาสนิมบริเวณเกลียว เราสามารถแก้ไขได้โดยใช้กาวกันสนิมเฮอร์มาซีล 55 เพื่อปกป้องเกลียวท่อ และข้อต่ออย่างสมบูรณ์

Herme Seal No.55 (500 g)

กาวเฮอร์มาซีล 55 (Herma Seal No.55) เป็นน้ำยาซีลป้องกันการผุกร่อน การรั่วซึมของน้ำใช้กับท่อเหล็ก ท่อไลน์นิ่ง อีกทั้งยังป้องกันการเกิดสนิมบริเวณเกลียว เหมาะสำหรับการเดินท่อจ่ายน้ำร้อน การเดินท่อจ่ายน้ำประปา

กาวเฮอร์มาซีล 55 ไม่มีสารเคมีที่เป็นอันตรายต่อมนุษย์ และมีประสิทธิภาพสูงในการป้องกันสนิม ตามมาตรฐานผลิตภัณฑ์ JWWA K142 (JAPAN WATER WORKS ASSOCIATION) ประเทศญีปุ่น

Color

Type of Film

Viscosity

Specific Gravity

Heated Residue

Diluent

Qty. 500 G / Can

: Gray

: Drying And Hardening

: 4,500 Cps. At 25 C

: 1.2

: 62 +- 3%

: Specified Solvent

– ใช้ผ้าเช็ดเกลียวท่อให้แห้ง เพื่อทำให้กาวเฮอร์เมสซีลเกาะติดผิวและเกลียวท่อได้ดี

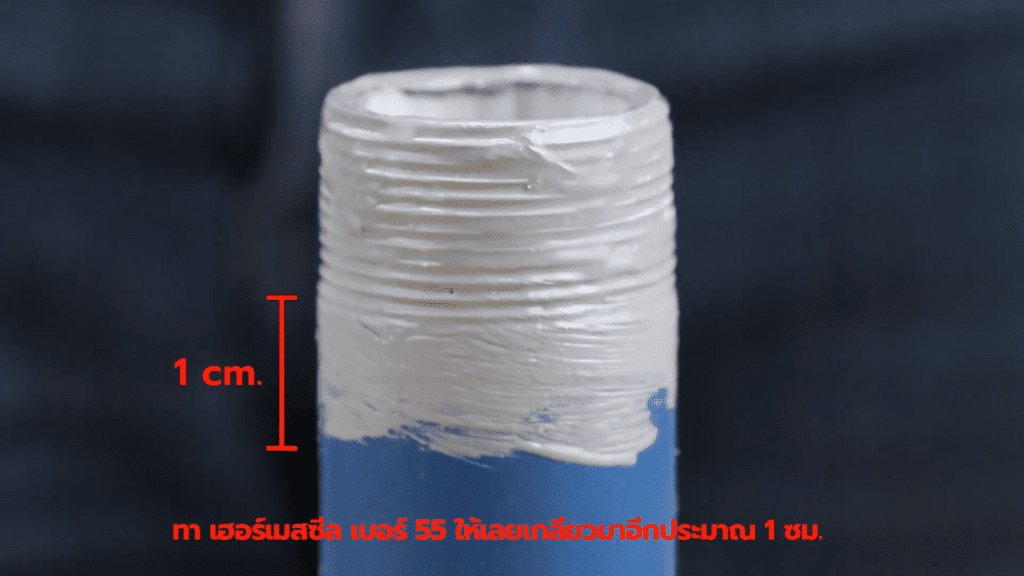

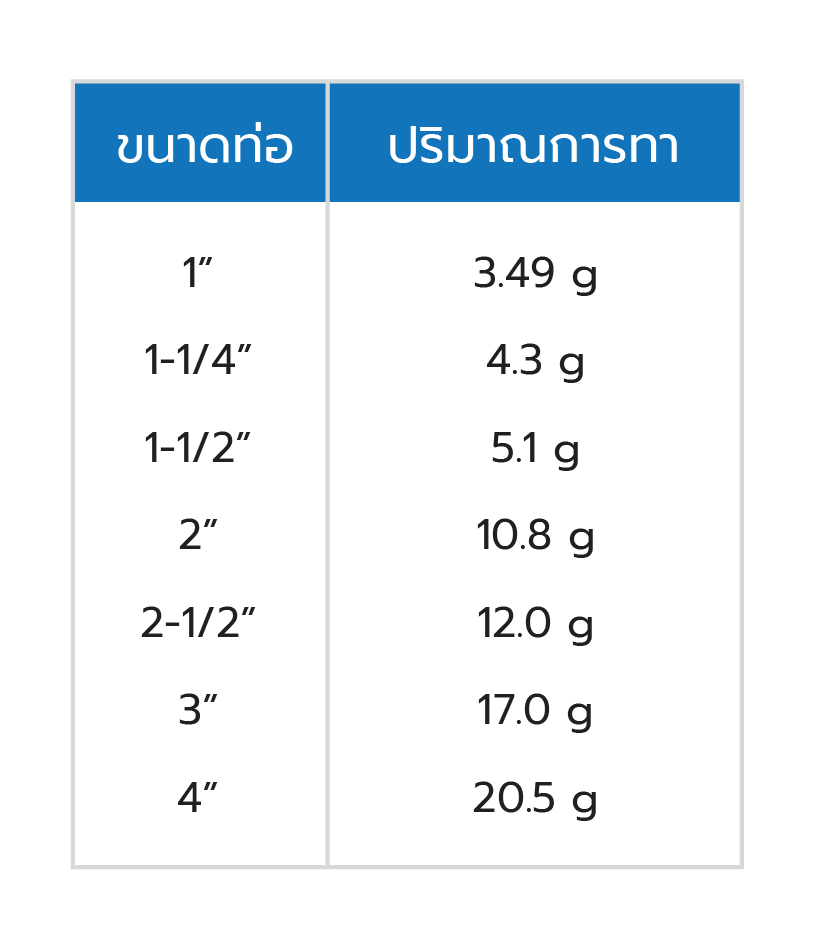

– ทากาวเฮอร์เมสซีล ตรงส่วนของเกลียวท่อ รวมถึงหน้าตัดท่อให้ทั่วบริเวณเกลียว และทาบริเวณเหนือเกลียวสุดท้ายขึ้นไปอีก 1-2 เซนติเมตร เพื่อป้องกันการเกิดสนิมกับเกลียวท่อ

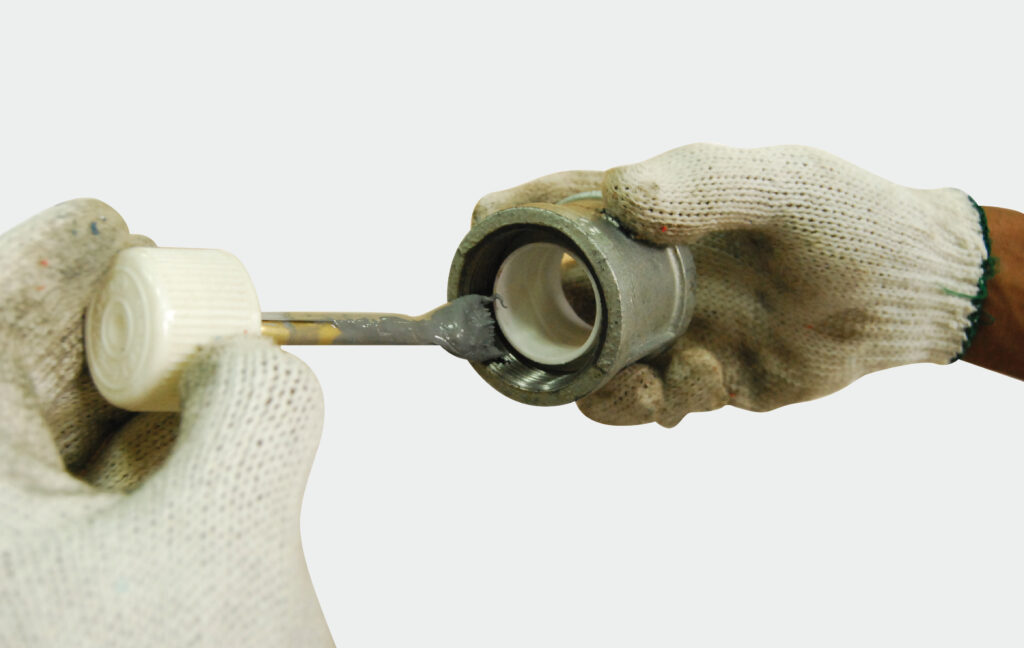

– ใช้เทปพันเกลียว หรือสายสิญจน์ พันที่เกลียวท่อประปา และทากาวเฮอร์เมสซีลอีกครั้ง เพื่อป้องกันเกลียวข้อต่อ จากนั้น ขันท่อเข้ากับข้อต่อ

กรณีที่ทากาวน้อยเกินไปจะทำให้กาวที่ทาไม่เต็มผิว ซึ่งมีผลต่อประสิทธิภาพในการป้องกันการรั่วของน้ำและการป้องกันสนิม นอกจากนี้ ในกรณีที่ทามากเกินไป จะทำให้กาวติดเป็นผลึกในท่อ และเป็นสิ่งเจือปนในน้ำที่ไหลออกมา

– ในส่วนที่ต้องให้ความสำคัญในการทากาวเฮอร์เมสซีลมากที่สุด คือ หน้าท่อตัด เพราะจะเป็นจุดที่อาจสัมผัสกับน้ำได้โดยตรง

– เนื่องจากกาวเฮอร์เมสซีลมีเวลาในการเกาะตัว ดังนั้นเพื่อเพิ่มประสิทธิภาพในการป้องกันการรั่วซึม และการเกิดสนิม จึงควรทิ้งระยะเวลาไว้อย่างน้อย 8-12 ชั่วโมง ก่อนการทดสอบปล่อยน้ำ เพื่อเพิ่มความแข็งแรง

– หลังการใช้งานกาวเฮอร์เมสซีล ควรปิดฝาให้สนิททุกครั้ง

หลังจากทำเกลียว ควรนำเศษเหล็ก น้ำมันต๊าป หรือสารหล่อเย็น ที่ตกค้างภายในท่อออกให้หมด เพื่อป้องกันการเกิดสนิมจากเศษเหล็กที่ตกค้างในท่อ และป้องกันไม่ให้มีกลิ่น อันเนื่องมาจากน้ำมันเครื่องต๊าป หรือสารหล่อเย็นที่ค้างอยู่ภายในท่อ นอกจากนี้เพื่อให้การป้องกันการรั่วและการป้องกันการเกิดสนิมบริเวณที่ทำเกลียวมีประสิทธิภาพยิ่งขึ้น ให้ทาบริเวณเกลียวของท่อและข้อต่อ รวมทั้งหน้าตัดท่อด้วยกาวเฮอร์เมสซีล 55 (โปรดดูรายระเอียด การใช้กาวเฮอร์เมสซิล) หรือ ทากาวเฮอร์เมสซีลที่เกลียวท่อประปาก่อนเพื่อปกป้องเกลียวท่อ แล้วพันเทปพันเกลียว หรือสายสิญจน์ ทากาวเฮอร์เมสซีลอีกครั้ง เพื่อป้องกันเกลียวข้อต่อ จากนั้น ขันท่อเข้ากับข้อต่อและทำการขันท่อตามรายละเอียดในตารางดังนี้

หลังจากการเชื่อมต่อเสร็จสมบูรณ์แล้ว ซ่อมแซมส่วนที่มีตำหนิบนท่อและข้อต่อโดยเฉพาะอย่างยิ่งบริเวณเกลียวด้วยสีกันสนิมหรือสารเครือบป้องกันสนิมเพื่ออายุการใช้งานที่ยืนยาวที่สุด โดยใช้สีน้ำมัน TOA GLIPTON เฉด 7357

สอบถามข้อมูลเพิ่มเติม โทร. 02-335-5777 กด 1 ฝ่ายข้อมูลสี

หลังจากการติดตั้งเสร็จ ควรปล่อยน้ำไหลเพื่อทำความสะอาดด้านในท่อและชำระสิ่งสกปรกที่อาจเกิดจากการติดตั้ง ด้วยส่วนผสมของคลอรีน (ใช้ได้ทั้งคลอรีนเหลวหรือส่วนผสมของโซเดียมไฮเปอคลอไรด์ สัดส่วนที่ใช้ไม่ควรน้อยกว่า 50 ppm) ทิ้งค้างไว้ในท่อไม่ต่ำกว่า 24 ซม. แล้วปล่อยน้ำสะอาดชะล้างจนกว่าสารคลอรีนที่ตกค้างคงเหลือในระบบไม่เกิน 0.2 ppm

การติดตั้งท่อเหล็กบุพีอีไซเลอร์ร่วมกับวาล์วประตูน้ำ (Gate Valve) เริ่มที่นำท่อที่ทำเกลียวแล้ว ต่อด้วยข้อต่อตรงเหล็กบุพีพี ต่อด้วยข้อต่อนิปเปิ้ลบุพีพี จากนั้นจึงขันเข้ากับวาล์วประตูน้ำ (Gate Valve) ทุกขั้นตอนติดตั้งตามขั้นตอนการติดตั้งแบบเกลียว(ทากาวเฮอร์เมสซีล 55 ทุกเกลียว)

177/1 อาคารบางกอกสหประกันภัย ชั้น 20 ห้อง 2 ซี ซอยอนุมานราชธน ถนนสุรวงศ์ แขวงสุริยวงศ์ เขตบางรัก กรุงเทพมหานคร 10500

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |